VERTICAL BELT TECHNOLOGY (VBT)

AquaPruf VBT

Our newest incline conveyor technology will save your facility both time and money. Here at Dorner, we have only FDA approved belting and plastic components in our AquaPruf series, including the VBT.

This vertical belt technology is used for elevating bulk products like vegetables and fruits, popcorn, grains and nuts, pet food, pharmaceuticals, and small packages. As a sanitary, vertical conveyor belt system, it’s ideal for food, pharmaceutical, chemical industries, and all sanitary environments as it carries out a wide range of applications.

The belt technology is built for steep and vertical inclines, as well as bulk material handling, food process, and as a washdown conveyor, is easy to clean. For more information on our latest, innovative technology, check out the features below or fill out the form on the right.

FEATURES OF VBT:

Applications

Elevation for walk-through

Hopper feeding

Weigh scale feeding

Sanitary environments

Open Frame/Tool-Less Sanitary Design

Continuous TIG Welded 304 stainless steel frame

#4 Polish on all surfaces

Open frame and tool-less design for ease of cleaning

Drive Gearmotor located on main column outside food drop zone

Staggered Sidewall Belt

Staggered Sidewall Belt provides 15% more pocket capacity than traditional sidewall belt

Self-Releasing Sidewall improves product release

Consistent RF Bonded Staggered Sidewall with 80% less bond area

Staggered Sidewall can be individually and easily repaired if damaged

Clean-through Side Wall Design improves clean-ability and reduces cleaning time and water usage

Quick Belt Change

Quick Change open-frame design allows belt change in approximately 20 minutes

Tool-less removal of idlers and belt supports

Loose belt drops down main column

No belt tensioning needed

Sizes

Lengths – Infeed and Exit

Minimum length = 20″

Maximum length = 72″

Length increments = 1/8″

Heights

Minimum TOB height = 16″

Maximum TOB height = 240″

Height increments = 1/8″

Speeds

Belt Speed up to 100 ft/min

Belting

Solid Urethane Belting with 2″ pitch positive drive lugs

3.5″ Tall RF welded scoop cleat

3.5″ tall RF welded staggered sidewall

Pocket Spacing

Minimum = 6″

Maximum = 18″

Spacing Increments = 2″

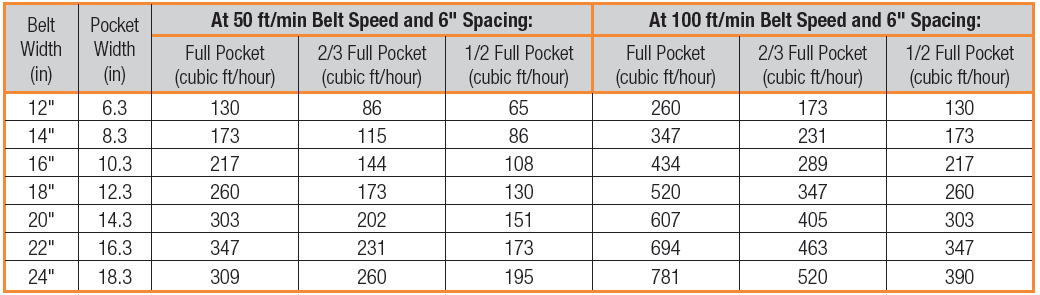

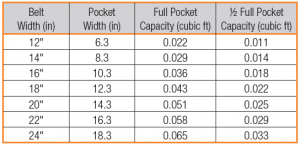

Maximum Product Capacity